Continuous Insulation (US)

Some Outsulation systems protect the underlying wall with an air- and water-resistive barrier under the rigid insulation, which maximizes the continuous insulation benefit. Outsulation systems can be installed in either “barrier,” “moisture drainage” or “pressure equalized” configurations, and these systems are engineered to perform in all climates and on all types of structures. On certain types of construction (high-rise) and in certain job conditions (cold weather), a prefabricated assembly method may be preferred.

There are multiple Outsulation® systems all with varied advantages based on building type and need. But the common characteristic of all of them is the presence of continuous insulation (CI) as an integral part of the system. The concept of insulation on the outside of the wall- or Outsulation®- has been a signature characteristic of the Dryvit solution- more than 40 years before model energy codes required it in commercial construction! See Outsulation Solutions by Dryvit, DS266 for system descriptions.

Continuous Insulation (CI) Systems by Dryvit

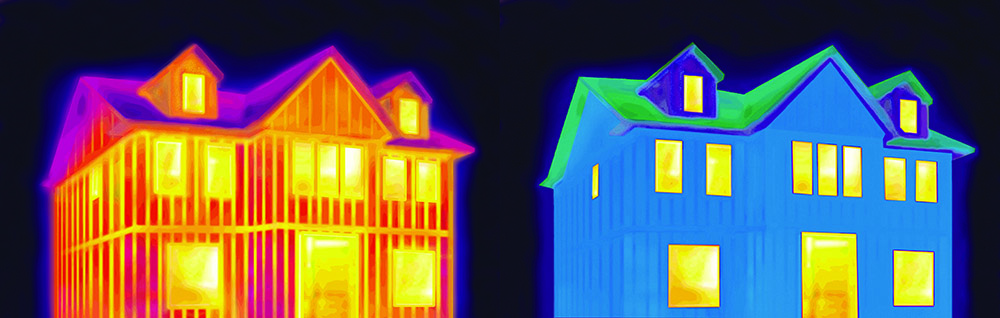

Thermal bridging at the stud line and its inherent energy loss is the single largest challenge with traditional framed buildings. According to the U.S. Department of Energy, the antidote to thermally inefficient, and largely under-insulated, buildings is Continuous Insulation (CI). National code bodies agree. In fact, CI has been required on most new construction since October 2013. When CI is incorporated into the building wall, thermal bridging is eliminated, controlling energy flow, conserving energy and reducing annual operating costs. That means lower heating and cooling costs year after year, and a more comfortable building for tenants, employees and customers alike. CI has been an inherent component of the Dryvit Outsulation® system since it was brought to the United States by Dryvit in 1969- truly a cladding system ahead of its time!

Continuous Insulation systems include:

• Outsulation

• Outsulation Plus MD

• Outsulation RMD

• Outsulation HDCI

• Outsulation LCMD 1-5

• Outsulation MD

• Outsulation PE

• Outsulation X

• Outsulation® Plus MD Securock® ExoAir® 430

• Outsulation® MD Securock® ExoAir® 430

• Outsulation® PE Securock® ExoAir® 430

• Outsulation® HDCI™ Securock® ExoAir® 430

• Outsulation® X™ Securock® ExoAir® 430

• Outsulation® Masonry Veneer System